2021

Sawdust Rotary Drum Drying Machine

drum drying machine for sale|wood rotary drum dryer

Sawdust is very common in life, and a large amount of sawdust is produced in various wood processing plants. This sawdust can be processed into various products such as sawdust compressed board and molded pallets. These sawdusts are usually dried when they are recycled. The sawdust rotary drum drying machine is specially designed for drying all kinds of sawdust. The drum dryer is specially designed for the drying of sawdust, small wood chips and wood residue. Sawdust dryer adopts high temperature and rapid drying process, equipped with biomass fuel hot air stove, high degree of automation, and good quality of dried products. The drying system is equipped with safe fire protection devices, hot air waste heat utilization and other devices. The entire drum drying machine has large output, low cost, and safe and reliable production.

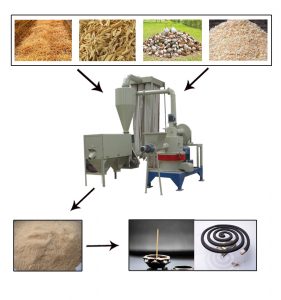

Raw material for sawdust drum drying machine

The sawdust drum drying machine can not only dry all kinds of sawdust, wood chips, and crushed waste wood, but also all kinds of materials containing wood fibers. For example, sawdust drum dryers are used to dry barley straw, oat straw, wheat straw, rye straw, rice straw, sorghum straw, and corn stalk, as well as potato vines, legume stalks, etc. Our company can optimize the drying process technology of the sawdust dryer according to the characteristics of each wood material, the size of the output, the application requirements, the cost control, and the convenience of operation.

Processing process of sawdust drum dryer machine

During the drying process, a screw conveyor is used to put the granular wet wood into the drying tube of the tumble dryer. The materials are constantly picked up and scattered under the inner lifting plate to realize heat exchange. Under the action of the high-speed hot air flow, the moisture in the wet material can evaporate, thereby obtaining a granular dry product. The equipment has a simple structure, convenient operation, high drying efficiency, good drying effect, and high degree of automation.

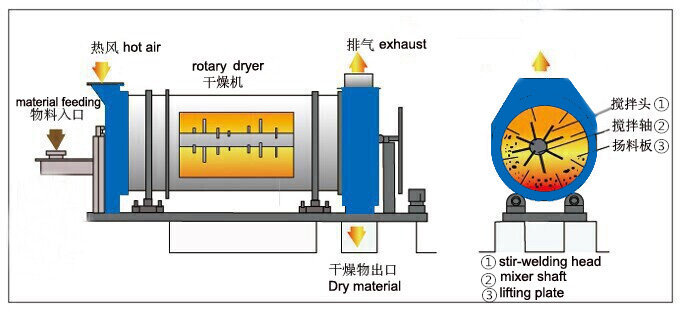

Structure of sawdust dryer

The sawdust drum drying machine includes a hot air stove, a feed port, a rotating drum, a motor, a material conveying pipe, a cooling drum and a discharge port. The rotating drum is located on the driving roller, and the driving roller is driven by the decelerating motor to rotate the rotating drum at a low speed. There is a feeding port between the hot blast stove and the rotating drum, and the rotating drum is equipped with a lifting plate. When the rotating drum rotates, the lifting plate will raise the material and mix the hot air evenly. One end of the filter cylinder of the sawdust dryer is connected with the rotating cylinder, and the other end is connected with the material conveying pipe. The bottom of the filter cylinder is provided with a slag discharge hole. One end of the cooling cylinder is connected with the material conveying pipe through a blower, and the other end is connected with the discharge port. Due to the above structure, the sawdust can be fully dried in the tumble dryer.

Features of sawdust rotary dryer

- The sawdust drum dryer machine is automatically controlled to ensure that the moisture of the dried sawdust is even and stable.

- Automatic stone removal and iron removal can ensure that the impurities in the dried wood chips are removed without affecting the quality of the product.

- The self-insulation thermal efficiency of the is as high as 70% or more. Equipped with a new type of energy-saving hot blast stove, high efficiency and energy saving.

- Using tail transmission, the transmission is more stable and reliable. At the same time, the drying time can be effectively controlled, and the drying effect is good.

- Using frequency conversion speed control to control the material flow, the moisture content of the wood chips after drying can be easily adjusted according to user needs.

We will reply you asap!

To You For You. ThoYu will always make every effort to respond to you quickly and competently. Please complete the form below and our service staff will give you quick and reliable feedback within 24 hours.

(required) You are reassured that the information which you provide to us is used fairly and held securely.