2021

The pallet block production line was shipped from Qingdao Port to Poland

On October 18, 2021, after intense and orderly production, ThoYu factory completed the customer’s order for the pallet block production line on time. According to the customer’s requirements, the goods are counted, loaded into containers, and shipped from Qingdao Port to Warsaw Port, Poland.

This time, Mr. Pete, who bought our pallet feet production line, is a long-term customer with us. The client is a well-known pallet rental company in the local area and has purchased pallet machinery from our company many times. Many waste pallets are generated in the customer’s business due to the aging and damage of wood pallets, which have been accumulated in the warehouse and cannot be effectively processed.

After communicating with our technicians, the customer wants to buy pallet block machine production line to process these waste wood pallets. This kind of production line is Automatic pallet block equipment improved on the basis of the original production line. Not only can effectively recycle waste pallets, but also some waste furniture. It solves the problem that some large pieces of wood cannot be effectively recycled. At the same time, we have improved the glue mixing process of the production line, so that no waste gas or waste wood is generated during the processing, and 100% of the wood is used.

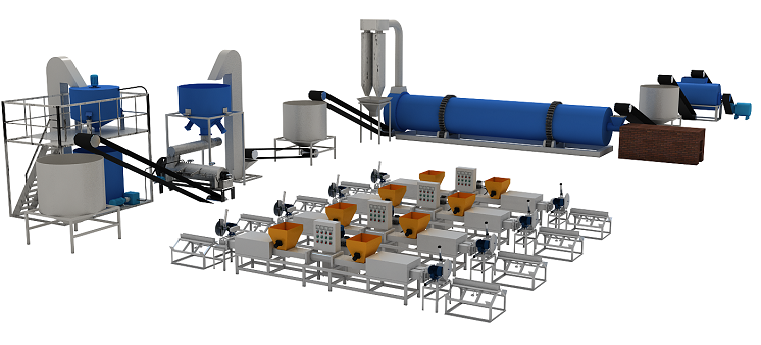

The customer wants to produce three kinds of plastic blocks of 145*145, 75*75, and 90*90, which are mainly used for the production of European pallets. The pallet block produced by the pallet block production line needs to be of high quality. Our engineers provide customers with 3D layout drawings based on the size of the customer’s factory (800 square meters of customer’s factory), combined with the space occupied by each machine in our production line. After getting a satisfactory answer from the customer, our engineers design and produce the pallet block production line.

The pallet block machine production line mainly includes comprehensive crusher machine, rotary drum drying machine, glue mixing machine, pallet block machine, and automatic cutting saw. The comprehensive crusher machine is mainly used for crushing waste wooden pallets. There is a screen on the machine, and the size of the sawdust particles after crushing can be adjusted by adjusting the size of the mesh. At the same time, the comprehensive crusher is equipped with iron removal equipment and dust removal equipment, which can remove iron nails from wood pallets and prevent a large amount of dust during machine operation. The rotary tumble dryer can remove the moisture contained in the wood chips. Because the humidity of waste wooden pallets is relatively high after long-term use, they need to be dried. Too much water in the sawdust will also affect the quality of the glue, and the produced pallet block will be mildewed. The three pallet block machines are equipped with three different molds and can produce three different specifications of pallet block. The automatic cutting saw can cut the pallet block, and the length can be adjusted according to requirements.

During the delivery period, our technicians completed the processing and assembly of the pallet block production line and conducted multiple tests on the production line. The quality of the pallet block produced is very good and can meet the needs of customers. According to the contract, start to prepare for delivery. After splitting and counting, a total of 154 pieces of goods, 15 equipment, and 5 containers were used for transportation. It takes 2 days to ship the goods, all of which are shipped in containers. In order to facilitate customers to count and sort after receiving the goods, we number each piece of goods and provide a detailed list of goods. Each machine has a corresponding certificate, installation instructions, and operating instructions.

It is ThoYu’s responsibility to do every product well and serve every customer well. We are honored to win the trust of customers and will do our best to provide customers with high-quality machines and services. After the customer receives the machine, we will contact the customer as soon as possible to provide the assembly, debugging, and production guidance of the pallet block production line. ThoYu can provide you with professional pallet block production solutions. If you have an investment in this area, please contact us.

We will reply you asap!

To You For You. ThoYu will always make every effort to respond to you quickly and competently. Please complete the form below and our service staff will give you quick and reliable feedback within 24 hours.

(required) You are reassured that the information which you provide to us is used fairly and held securely.