2021

how to make a good sawdust presswood pallet

With the development of the logistics industry, the market demand for pallets is also increasing. Pallets have been widely used in various industries, mainly for logistics, warehousing, and transportation. Because sawdust presswood pallet is relatively strong and relatively inexpensive, they have become more and more popular. The panel and 9 supporting feet are molded at one time by a sawdust pallet press machine. The entire pallet is not connected by nails and is very strong.

Advantages of sawdust molded pallets

The moisture content of the sawdust presswood pallet is usually relatively low, generally controlled between 6% and 8%, and the pallets do not absorb moisture during use. In the process of use, the size is stable and not easy to deform. The product has high dimensional accuracy and specially designed reinforcing ribs to ensure the strength of the product. The rounded corners of the pallet are designed to prevent the product from being scratched during use. When stacking, multiple pallets can be stacked together, occupying a small space, and the same number of pallets can save 3/4 of the space compared with ordinary wooden pallets. A wide range of raw materials can be used for processing, and all kinds of waste wood can be used to produce sawdust presswood pallet. The product is environmentally friendly and can be recycled and reused, with low pollution and a high recovery rate.

Production process of molded presswood pallets

Choose raw materials

The production of the sawdust presswood pallet must first select the appropriate wood material. There are many kinds of waste wood in life, and most of them can be used to produce molded pallets. Such as processing residues and leftovers produced by various wood processing plants. Sawdust, shavings, branches, and bark can all be used to produce molded wooden pallets. Plant stalks, rice straw, bamboo, miscanthus, and coconut shreds produced by some farms are also raw materials for the production of wooden pallets.

Crushed raw materials

After selecting the materials, the wood must be crushed. Large pieces of wood cannot be directly used to produce pallets. The wood can be crushed with a wood crusher machine. The wood is transported to the wood crusher machine, and the blade in the machine can smash the wood into small particles under high-speed rotation. The screen below the wood crusher can control the size of the wood particles.

Mix the raw materials

The crushed wood needs to be mixed with a glue mixer machine. The glue mixing machine is a machine that evenly mixes glue and raw materials, and is widely used in molded pallet production lines. After the raw materials are weighed, they enter the glue mixing machine continuously from the feed port. Under the action of the feed shovel, the raw materials move in the circumferential direction, and the glue enters the glue mixing machine in the tangential direction and is stirred by the stirring rod to fully mix the glue and the raw materials.

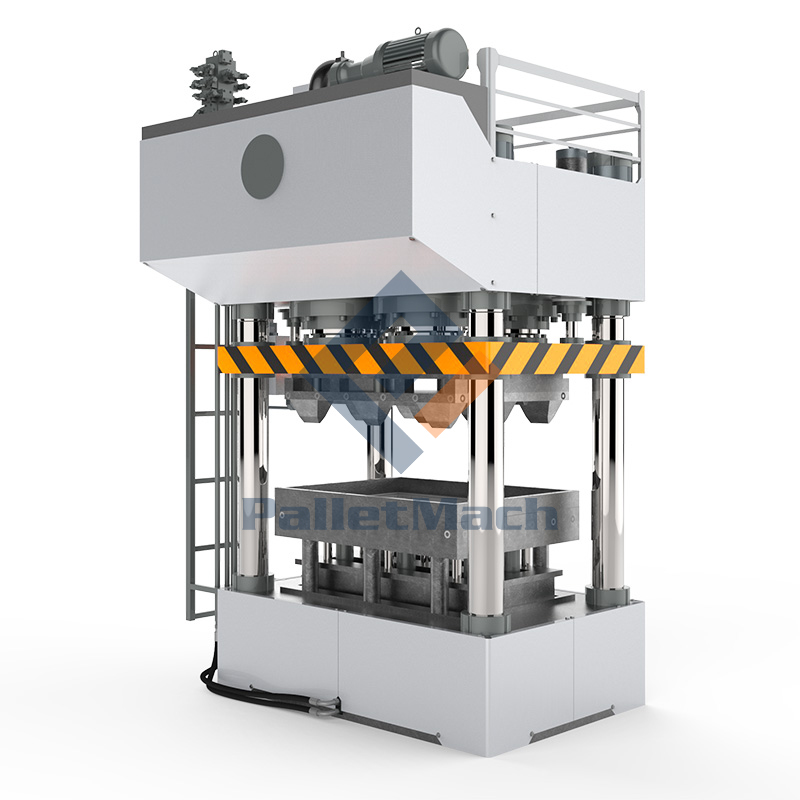

Molded raw materials

Molding the mixed raw materials is the last step in the production of molded pallets. The quality of molding directly determines the quality of molded pallets. The weighed raw materials enter the mold of the wooden pallet molding machine, and the paving device on the machine flattens the raw materials. Under the high pressure of the hydraulic system that presses the wooden pallets, the raw materials are formed into pallets in the mold of the machine.

What do you need to know when producing molded pallets

1. Anything containing wood fiber can be used as a raw material. Usually, bagasse, bamboo, waste wood, short wood, straw, etc. are used. Therefore, a wide range of raw material sources saves the manufacturing cost of the product. You can choose the raw materials according to the industry you are engaged in and the waste wood you want to process.

2. Collect raw materials containing wood fibers and some waste wood materials usually contain impurities. Large pieces of sand and gravel need to be removed with a screening machine. If there is too much soil, the raw materials should be washed and dried. In order to ensure that the raw materials and glue are uniformly mixed, the moisture content of the dried raw materials should be maintained at about 5%.

3. Molded pallets of different sizes can be produced through different molds. We can customize the mold according to your needs. The performance of the pallet depends on the quality of the raw materials and glue you choose. In actual use, the measurement of pallet performance depends on static and dynamic loads. Generally speaking, the larger the size of the pallet, the greater the load.

We will reply you asap!

To You For You. ThoYu will always make every effort to respond to you quickly and competently. Please complete the form below and our service staff will give you quick and reliable feedback within 24 hours.

(required) You are reassured that the information which you provide to us is used fairly and held securely.