- Hot-selling Wood Pallet Shredder - Compressed Pallet Machine,Presswood Pallet Mould Machine – ThoYu -

Hot-selling Wood Pallet Shredder - Compressed Pallet Machine,Presswood Pallet Mould Machine – ThoYu

Introduction of sawdust pallet press machine

Processing technology of pallet compression machine

Presswood pallets equipment is a set of molding pallet forming machinery independently developed by our company. The raw material of the pallet press machine for sale is different, and the processing technology is also different. Usually waste wood, wood chips, shavings are used as raw materials, dried with a roller dryer, mixed with glue, and then hot-pressed once to make compressed wood pallets. If bulk wood is used as raw material, wood chipper and wood crusher are also needed to break the wood. After drying and mixing, the sawdust is laid in the mould of press wood pallet making machine. Driven by the hydraulic system, the upper and lower mould is closed. In the process of processing, just spread the sawdust in the mold, operate the work button, the sawdust mould press machine can automatically complete all the work. In the process of processing, the material is placed in the mold of the wood pallet molding machine. The pallet molding machine can automatically complete the whole process of pressing, holding pressure, timing, pressure relief, demoulding and lifting.

Technical parameters of pallet molding machine

| Model | single station PM-1000 | double station PM-1000D |

| Raw materials: wood chips, waste wood, flax, sugar cane bagasse | ||

| Pallet size: :1.2×1.0m/ 1.2×0.8m( accept customized) | ||

| Main structure: 3 beam 4 column | ||

| Material: framework Q235A; column: 45# mold: 45# | ||

| Pressure:1000 (Ton) | ||

| Support LOGO customized | ||

| Pallet weight: 18Kg / 20Kg /22Kg;Dynamic load: 1.5-2 Tons;Statics load: 6-9Tons | ||

| Smart Gateway: Running state, production capacity and program control can be managed online. | ||

| Electronic component: Schneider; PLC: Siemens or Mitsubishi;Screen: Weview; Servo motor brand: Albert | ||

| Capacity: | 160-180 pcs/24h | 220-240 pcs/24h |

| Mold number: | one upper mold and one lower mold | one upper mold and two lower molds |

| Dimension | 2000x1800x4850mm | 4800x2100x5250mm |

| Weight | 22 Tons | 37 Tons |

Single station pallet molding machine

There is only one set of molds in the single-station pallet molding machine, and a certain waiting time is required when the machine is loaded, pressed down, maintained pressure, and opened the mold. The efficiency of the machine’s processing pallet is not as high as that of the double-station pallet molding machine.

Double station pallet molding machine

The double-station press machine is a popular pallet processing machine on the market. Due to higher production capacity and more energy saving, it is favored by more and more pallet processing plants. There are two sets of molds in the double-station press that can process pallets in turn, and the processing efficiency is higher. The two sets of molds can move in parallel under the drive of the servo motor. When one set of molds is used to hold the pressure and shape the pallet inside, the other set of molds can be used for feeding, adding the raw materials into the mold and flattening it. The double-station press is independently developed by our company in order to solve the low processing efficiency of traditional compressed pallets in production practice. It has completely independent intellectual property rights. The machine runs stably and greatly saves the time required for processing a single pallet. The machine cost of the double-station pallet press is not much higher than that of the single-station press, but the production capacity is greatly improved. At present, it has become the mainstream molded pallet processing equipment on the market.

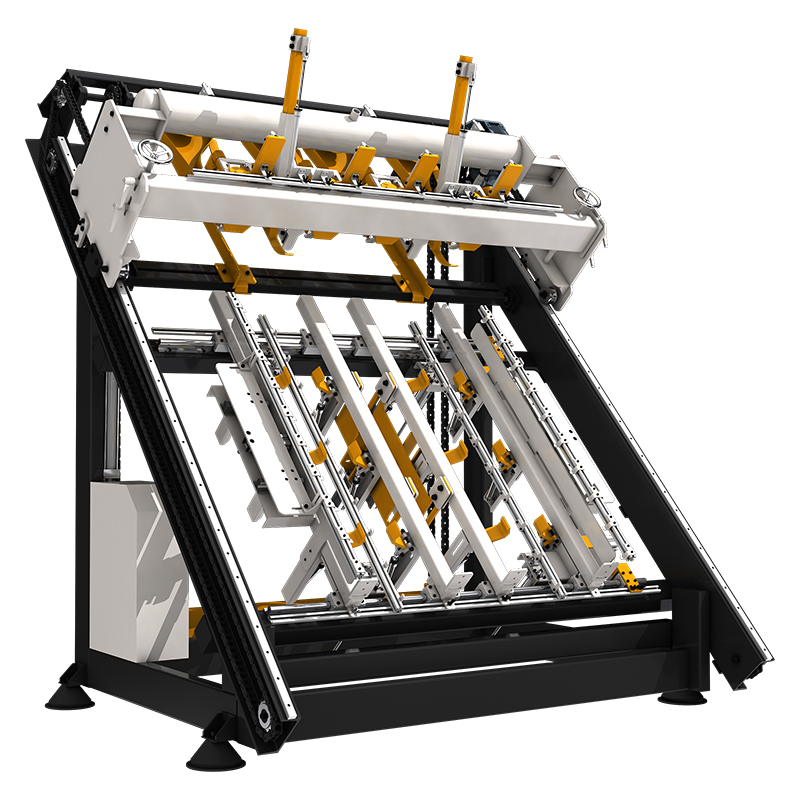

Structure of sawdust pallet press machine

The single station pallet press machine and the double station pallet press machine are similar in structure, but the main mould part is different. Due to the higher capacity of the double station wood pallet machines, the processing time of the compressed pallet is shorter and the energy consumption is lower, so it is more popular in the market at present. The whole sawdust pallet making machine is divided into frame part, electrical part, hydraulic part, mold part. The four parts cooperate with each other to complete the production of molded pallets.

Features of wood pallet press machine

Raw material for compressed wood pallet machine

Advantages of wood pallet hydraulic machine

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.