In the plastic pallet manufacturing sector, while virgin PP and PE are common, mixed plastic waste is emerging as a valuable resource. This article introduces an innovative technology that transforms Paper Mill Plastic Waste into durable molded pallets, proving that this waste is not trash but a misplaced resource.

The Untapped Potential of Paper Mill Plastic Waste

Large paper mills generate tons of derivative waste daily alongside paper production. These mountainous waste piles are not only difficult to dispose of but also incur significant handling costs. The key question is: how can we manage this waste properly and maximize its resource value?

What is often seen as a liability is, in fact, a potential resource mine. The vast amounts of Paper Mill Plastic Waste can be efficiently upcycled into strong, reliable plastic pallets using advanced technology.

The Conversion Path: From Waste to Premium Pallets

Leveraging extensive experience from successful projects in Shandong, China, and the Philippines, ThoYu has collaborated with partners to develop and establish a full production line for creating molded pallets using Paper Mill Plastic Waste as the primary raw material.

After on-site inspections, ThoYu’s team found that the volume and composition of the client’s Paper Mill Plastic Waste exceeded expectations. This waste stream is rich in plastic content, holding significant recycling value.

Initial raw material testing has been successfully completed, securing a stable and high-quality feedstock source for future pallet production. This conversion pathway is clear, offering substantial economic and environmental benefits.

Core Technology: Overcoming the Challenges of Complex Waste

Paper Mill Plastic Waste is complex and has high impurity content, with processing difficulties concentrated in cleaning, separation, and plasticization. ThoYu’s advanced raw material processing solution tackles these challenges effectively.

Click the link below to view the trial content of the Paper Mill Plastic Waste:

(21) ThoYu Turns Paper Mill Waste into Sustainable Profit – YouTube

Precision Pre-Treatment: From Impure to Pure

Shredding + Multi-Stage Washing + Paper-Plastic Separation: This process step-by-step removes impurities like sand, paper fibers, and metals, ensuring the plastic purity meets production requirements.

(Paper Mill Plastic Waste)

Dewatering & Plasticizing: Wet material with 40%-50% moisture content is processed in one step to achieve ≤5% moisture, simultaneously achieving initial plasticization and forming uniform pellets, ready for extrusion.

Advanced Molding Technology

Multi-Stage Extrusion + Quantitative Dosing: A multi-stage extrusion system ensures thorough plasticization and degassing. Coupled with ThoYu’s proprietary dosing system, it precisely controls material input, guaranteeing product consistency.

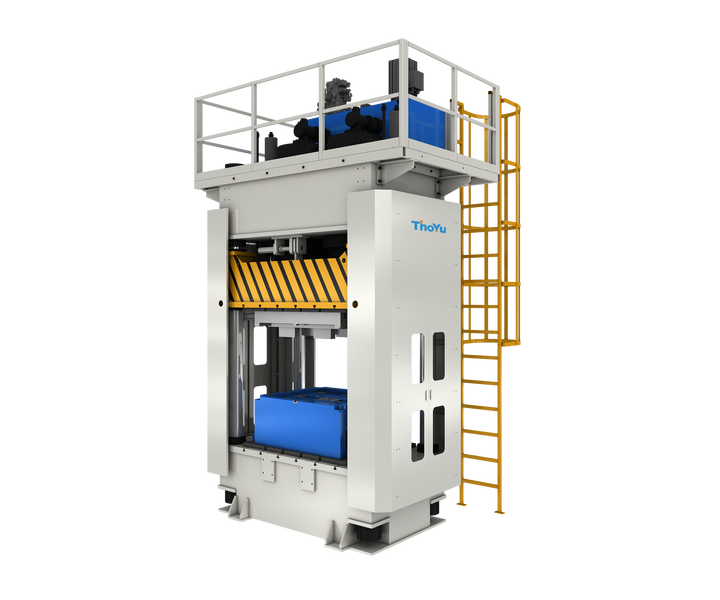

ThoYu Molding Press & Custom Molds: High-tonnage cold press molding technology, combined with an automated mold system with built-in cooling channels, enables rapid pressure holding (120-180s) and efficient demolding.

(ThoYu plastic pallet machine)

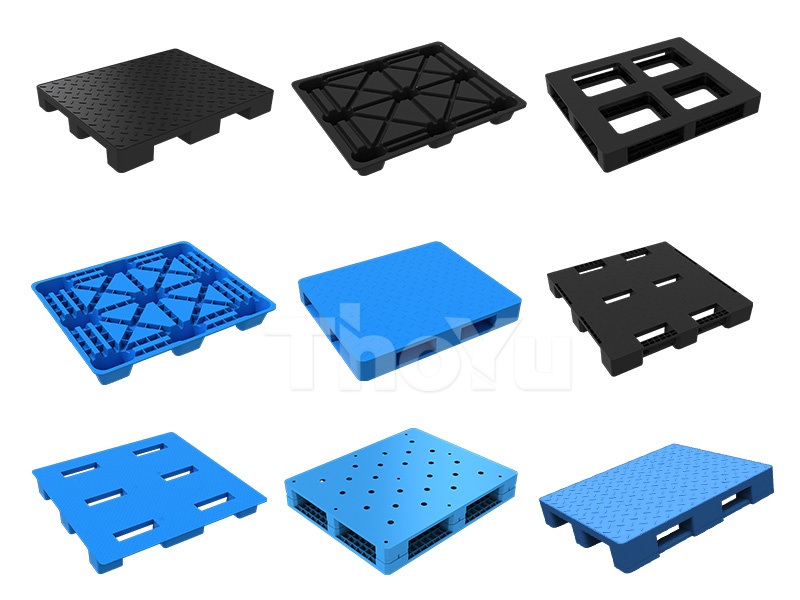

(Various pallet styles)

The Triple Revenue Advantage

Converting Paper Mill Plastic Waste into plastic pallets offers a triple-profit model:

Near-Zero Raw Material Cost

This Paper Mill Plastic Waste, often a disposal burden, primarily incurs only transportation costs. Through proper recycling, you gain long-term, stable access to a massive, virtually free raw material source.

Clear and Visible Profit

Leveraging ThoYu’s mature process, approximately 20 standard pallets can be efficiently produced from every 500kg of Paper Mill Plastic Waste. Based on current market prices ($7-$15 USD per pallet, equivalent to 50-100 RMB), each production batch translates to fast and considerable market returns.

Stable Long-Term Returns

ThoYu equipment, built with precision casting for durability, has a service life exceeding 10 years. Based on this low-cost, high-value operational model, clients can typically achieve ROI within the first year, generating pure profit thereafter and creating a reliable long-term “wealth engine.”

The next time you look at discarded plastic, your perspective will likely be different. This former “waste” is, in reality, an untapped valuable resource.

Post time: Nov-14-2025