The 2025 Malaysian Wood Expo in Kuala Lumpur has just concluded.

Held from November 10th to 12th at the Malaysia International Trade and Exhibition Centre (MITEC), this edition covered an exhibition area of 24,000 square meters. It brought together 127 exhibitors from 19 countries, including China, Germany, and Austria, and attracted over 3,000 professional trade visitors.

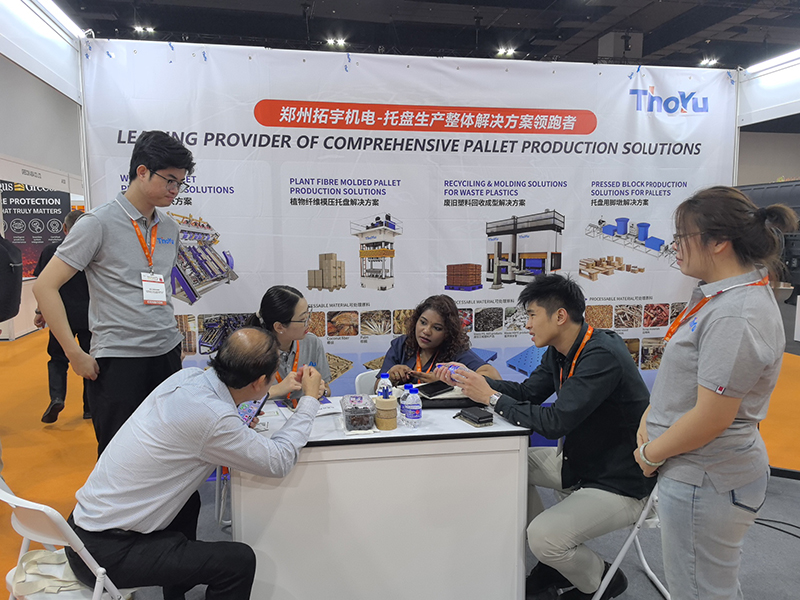

(A corner of the booth)

(All set and ready)

(Group photo at the ThoYu team booth)

Although the event lasted only two days, the venue was consistently bustling with activity and enthusiasm.

At Tuoyu’s booth, clients paused to watch equipment demonstration videos, carefully read product brochures, or engaged in in-depth discussions with our sales team.

The interactions were natural and friendly, with evident joy on everyone’s faces upon gaining new knowledge – perhaps this is the unique charm of physical exhibitions.

(ThoYu’s booth crowded with visitors)

What impressed us was that, besides professional buyers, many students specializing in mechanical engineering and environmental protection came for research, showing the next generation’s interest in technology and innovative equipment.

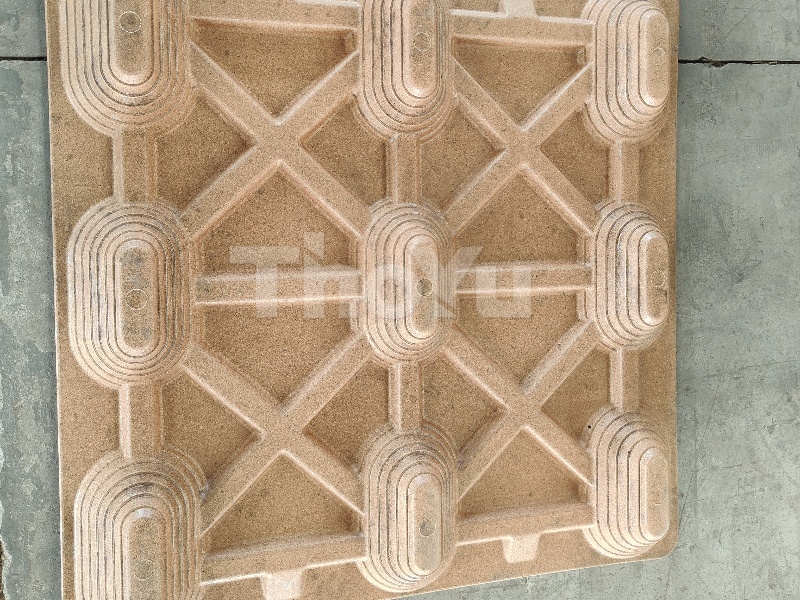

(Clients showing great interest in the molded pallet samples)

(Sales staff cordially receiving client inquiries)

(Becoming friends with clients)

The exhibition also yielded substantial business progress: we have connected with over a dozen potential clients specializing in pallet production and plan to conduct site visits and further negotiations post-show. Meanwhile, eight long-term partners of ThoYu, due to their own business expansion, plan to embark on new collaborations with us.

Unlocking the Value Code of Waste Materials

At ThoYu’s booth, factory owners and procurement managers from Malaysia, Vietnam, and Indonesia held our displayed pallet samples, curiously asking, “We have piles of such waste materials back at our place. How exactly do you turn them into pallets?”

Over the two days, more than 80% of the clients were concerned with the same issue: as international timber prices continue to rise, the production cost of wooden pallets has become a heavy burden for businesses. Besides traditional timber, are there any ideal alternative materials that are both economical and practical?

Tuoyu’s production solution for plant fiber molded pallets is the perfect answer to this challenge. We are dedicated to transforming commonly found agricultural and forestry residues – such as coconut shells, palm kernels, straw, and dozens of other types of “agricultural and forestry waste” – into sturdy, durable, and precisely sized molded pallets through innovative technology. This is not only a smart move to reduce costs directly at the source but also a strategic step towards green, circular production.

Coconut Shells

Billions of coconuts are processed annually, generating vast amounts of shells that are typically burned or discarded across Southeast Asia. At Tuoyu’s booth, waste coconut shells were transformed into high-quality pallets with surfaces as smooth as an oil film and precise dimensions without burrs.

(Raw coconut shell materials and finished product display)

Palm Shells

Malaysian palm plantations produce hundreds of tons of palm kernels daily. Stockpiling them outdoors causes environmental pollution and incurs disposal costs. Tuoyu’s solution turns these “liabilities” into sturdy and durable pallets.

(Raw palm Shell materials and finished product display)

Kenaf Stalks

Addressing the challenges of kenaf stalks being lightweight, low-density, and troublesome to handle, coupled with Malaysia’s stringent environmental standards, Tuoyu’s technical solution successfully achieved the efficient conversion of waste kenaf stalks into green pallets.

(Raw kenaf stalk materials and finished product display)

Collaborating for a Shared Future

The fact that 80% of clients at the exhibition raised the same question reflects a common pursuit across Southeast Asia for green manufacturing and the circular economy.

The reason ThoYu’s solution resonates so widely is precisely that it achieves localized sourcing, green cycling, technological advancement, and cost optimization.

A manufacturer from Vietnam voiced the shared sentiment: “We don’t lack raw materials; we lack the technology to turn waste into valuable products. What Tuoyu offers is exactly the solution we need most.

Post time: Nov-13-2025