Facing a global recycling rate of only 20%, ThoYu’s Xinjiang model offers a breakthrough. By transforming discarded mulch film into high-strength plastic pallets through innovative water-free sorting and direct moulding, it turns “white pollution” into a sustainable, closed-loop resource.

The Global Perspective on Used Mulch Film Recycling

In the realm of agriculture, plastic materials play a crucial role. Globally, the annual consumption of agricultural plastics exceeds 13 million tons; however, the overall recycling rate remains disappointingly low at approximately 20%. While countries like the European Union and Japan boast recycling rates of over 80%, regions such as Xinjiang, China, have achieved impressive rates of 85% to 90%. Despite these successes, significant challenges persist, including high recycling costs, the difficulty of recycling ultra-thin mulch film, and the instability of biodegradable films.

The Pollution Dilemma Behind Mulch Film Recycling

The use of mulch film technology can dramatically increase crop yields per acre, yet the long-term application results in used mulch film accumulating in the soil. This accumulation disrupts soil structure, impedes root development, and ultimately leads to reduced crop yields. Traditional disposal methods, such as landfill usage, occupy valuable land while polluting the soil. Incineration, on the other hand, generates harmful gases.

(used mulch film)

(The separated raw materials)

ThoYu has established a demonstration base in Xinjiang for used mulch film recycling, utilizing innovative technology that not only effectively addresses the persistent problem of agricultural “white pollution” but also transforms discarded mulch film into plastic moulded pallets.

Water-Free Processing and Smart Sorting

The primary challenge in recycling discarded mulch film from Xinjiang cotton fields lies in the arduous task of separation and purification.used mulch film often intertwines severely with cotton stalks and soil, making traditional water-intensive cleaning methods not only inefficient but also problematic in a water-scarce region.

By introducing water-free air separation technology, ThoYu effectively tackled the challenges associated with water washing.Coupled with intelligent shredding and automated mechanical sorting, this process replaces inefficient and costly manual sorting, achieving high efficiency and fine separation of used mulch film from impurities.

This method not only significantly boosts separation efficiency and reduces overall costs but also ensures a clean raw material supply for subsequent deep processing.

Direct Moulding Without Granulation

Following the meticulous separation and cleaning processes, the recycled mulch film is ready to be directly utilized in production lines at ThoYu, eliminating the need for additional granulation.

This innovative “from used to product” model, which directly processes recycled plastic into end products, avoids energy consumption and performance loss associated with intermediate granulation stages.

Through the use of high-efficiency plastic extruders, the used mulch film is heated, melted, and uniformly plasticized. The molten material is then fed into ThoYu’s self-developed compressed plastic machine, which completes the molded of plastic pallets in one step under high temperature and pressure conditions.

(high-efficiency plastic extruders)

Since the latest batch of equipment has been successfully tested and is now operating smoothly at the Xinjiang demonstration base, a significant amount of discarded mulch film is being transformed daily into plastic pallet products.

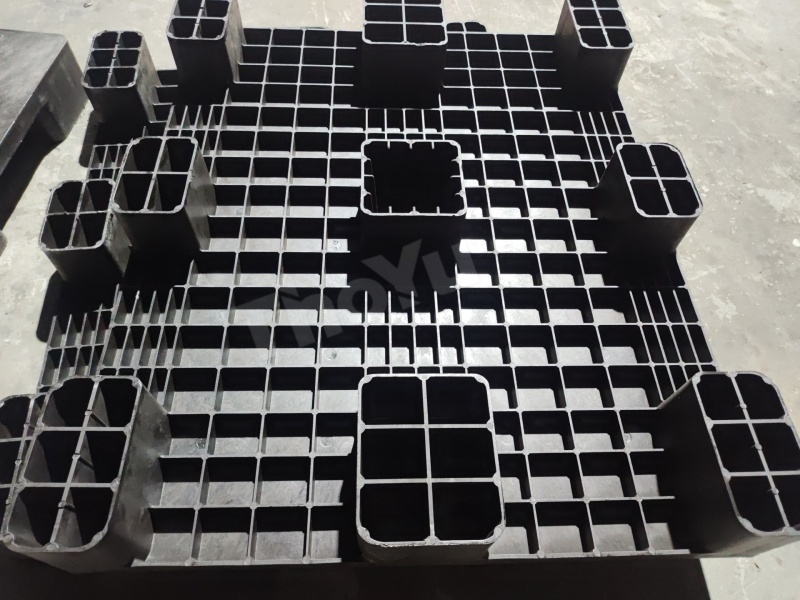

(Plastic pallets molded with used film)

Moulds made from P20 mould steel guarantee that every finished product meets high standards in terms of thickness uniformity, edge smoothness, correct hole placement, and surface finish.

These pallets can support dynamic loads of up to 1.5 tons and static loads of 6 tons, fully meeting the general requirements of warehousing and logistics.

Customization of moulds is also supported, allowing flexibility to adapt to diverse client specifications for pallet sizes and styles.

Validating a Model: Ecological and Economic Benefits

Since its establishment in March 2023, the Xinjiang demonstration base has successfully recycled nearly 40,000 tons of used mulch film, achieving a resource utilization rate of over 85%. The company has the capacity to recycle and process 30,000 tons of used mulch film annually, producing both plastic pallets and plant fiber pallets. With increasing sales of specialty agricultural products such as Jujubes and local tomato sauces, the demand for pallets continues to rise, providing a stable market outlet for the project.

Post time: Feb-04-2026