In a significant achievement on December 4, 2023, ThoYu showcased its expertise by successfully overseeing the installation and commissioning of an advanced plastic molding pallet production line for a prominent Iranian client. Boasting a highly skilled after-sales installation team, ThoYu ensured a seamless execution of the project, with comprehensive testing validating the production line’s efficiency in crafting durable plastic pallets. The client expressed profound satisfaction with both the superior machinery and the exemplary services provided by ThoYu.

The client, a distinguished confectionery conglomerate renowned for its high-quality cocoa, chocolate, and candy products on a global scale, embarked on an ambitious journey to establish an in-house pallet production line. After an extensive market analysis, ThoYu emerged as the preferred partner for the client, chosen to develop a fully automated plastic pallet production line.

The collaborative venture commenced on June 2, 2022, marked by the official signing of the contract between the Iranian client and ThoYu. The client’s requirements were comprehensive, seeking a turnkey solution covering the pre-processing of waste plastic, including raw material cleaning and dehydration, extrusion, and final molding. The primary raw materials for recycling comprised discarded plastic barrels, bottles, and films, with a daily production output of 400 pieces intended for warehousing and efficient transport of supermarket goods.

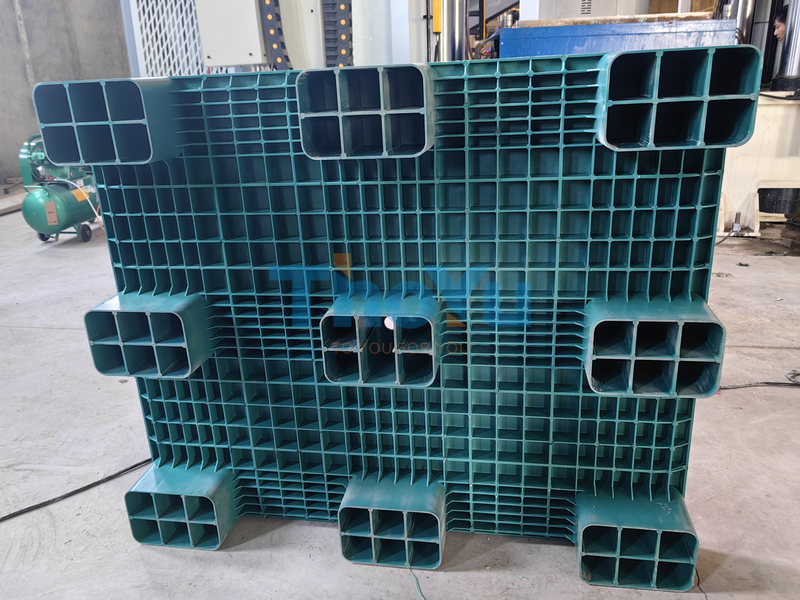

To address the client’s specifications meticulously, ThoYu’s adept technical team engaged in detailed planning, ensuring the optimal design of the production line and the corresponding manufacturing facility. The waste plastic barrels underwent precise crushing using a cutting-edge waste crusher, while a sophisticated cleaning machine and dehydrator guaranteed thorough drying of raw materials. An advanced extruder machine transformed the raw material into a molten state, and the precision of the plastic pallet press molded the molten plastic into the desired pallet shape. The pinnacle of efficiency was achieved through the incorporation of robotic arms, facilitating seamless retrieval and stacking of the pallets, resulting in a fully automated production line.

This plastic pallet production line excels in high production efficiency and distinguishes itself for its significant contribution to waste plastic recycling. ThoYu’s commitment to environmental sustainability is evident in the energy-efficient and highly automated nature of the entire production process, leading to a substantial reduction in labor costs. In comparison to traditional plastic pallet injection molding and blow molding equipment, the equipment cost of this cutting-edge production line is notably lower, providing the client with an economically sound and environmentally responsible solution.

If your company shares similar requirements, we encourage you to reach out to us. ThoYu’s unwavering dedication to delivering professional plastic pallet production solutions remains steadfast, poised to contribute to the growth, efficiency, and success of your business.

Post time: Dec-13-2023