As a deep cultivator in the field of molded pallet equipment, ThoYu leverages years of production line R&D experience to integrate proprietary core technology into every detail of the pallet trimming workstation creating an intelligent device that is truly tailored to industry needs and practical production.

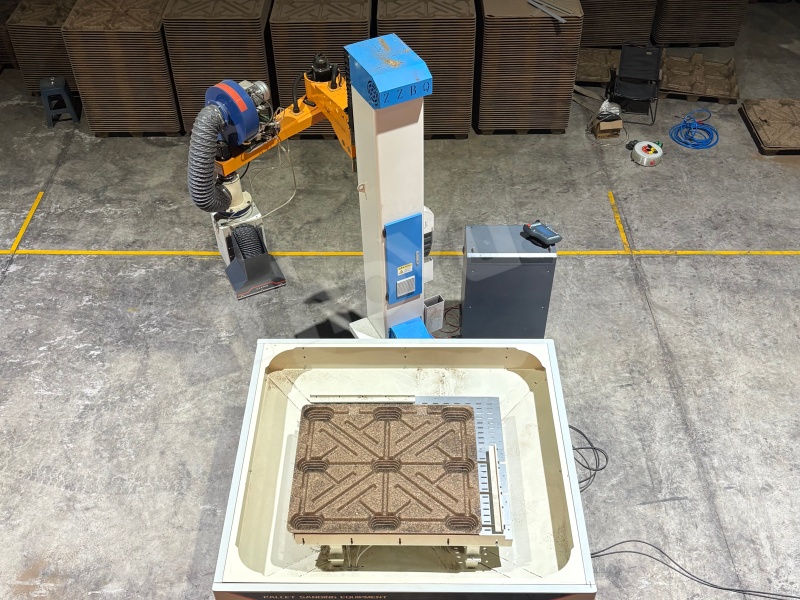

This workstation consists of an edge-trimming robotic arm and a high-precision positioning platform. All core components undergo rigorous testing to ensure stable operation in high-intensity production environments. It perfectly synchronizes with the rhythm of ThoYu’s self-developed compressed pallet machine, enabling an efficient “one-services-two” collaborative mode while also supporting manual operation for flexible adaptation to diverse production needs.

(Actual photo of the pallet trimming workstation)

The ThoYu pallet trimming workstation is exclusively designed as a supporting device for ThoYu’s molded pallet production lines and is not sold separately. Its purpose is to provide cooperative clients with a complete, integrated production solution, ensuring seamless line connectivity.

Fully Unmanned Process, Fortifying Production Safety

ThoYu eliminates the drawbacks of traditional manual edge-trimming by adopting a fully automated robotic arm design. The entire process—from pallet loading and precise positioning to edge grinding, dust removal, and palletizing—requires zero manual intervention.

This design not only completely liberates workers from dusty, high-risk environments, eliminating occupational injury hazards, but also enables stable, uninterrupted 24/7 production. It breaks through the time constraints and efficiency fluctuations of manual labor, making production safer and more efficient.

(Actual photo of the pallet trimming workstation)

High-Precision Control, Setting the Standard for Quality

Powered by program control, the edge-trimming robotic arm achieves a repeat positioning accuracy of ≤0.1mm. It strictly follows preset paths to complete edge chamfering and grinding, ensuring highly consistent results for every pallet—from the 1st to the 1000th.

Furthermore, the workstation can precisely execute complex C-edge grinding that is unattainable manually, refining product details and significantly enhancing the pallet’s appearance and tactile quality, thereby boosting market competitiveness.

Flexible Adaptation for Multi-Specification Production

To meet the production needs of various molded pallet specifications, the ThoYu Edge-Trimming Workstation is equipped with a flexible control system. No hardware changes are required; simply switching the corresponding processing program in the system allows the robotic arm to automatically adjust parameters, quickly adapting to edge-trimming tasks for different pallet sizes.

The ThoYu Pallet Trimming Workstation represents a systemic upgrade for molded pallet production, aiming to create tangible value for you across four dimensions:

Efficiency Leap: Enables stable 24/7 continuous operation, breaking through manual production capacity bottlenecks.

Cost Reduction: A single unit replaces two or more workers, comprehensively saving labor, management, and consumable costs.

Outstanding Quality: Standardized, high-precision grinding ensures consistent quality for every pallet, enhancing brand image.

Management Ease: Simplifies frontline management and eliminates high-risk operations, making production management more efficient.

The ThoYu Molded pallet trimming workstation is now open for production line integration. We sincerely invite partners for on-site experience. We will customize a seamless integration plan based on your specific needs for rapid deployment, jointly opening a new chapter in efficient production.

Post time: Feb-06-2026