Late at night in a Japanese factory, piles of black cable skins release a sharp, persistent odor—this industrial waste, long deemed “unrecyclable,” sits waiting for renewal. Now, the benchmark project delivered by ThoYu stands as living proof of that transformation. As the industry’s first initiative to successfully produce eco-friendly cable skins pallets on a large scale from complex cable-derived materials, it breaks technical boundaries and breathes new life into stubborn waste.

(black cable skins waste)

I. The “Impossible” Transcontinental Challenge

ssible” Transcontinental ChallengeIt started with a phone call from Japan in July 2023. A client, struggling with large volumes of discarded cable skins (rich in PVC and rubber), reached out to ThoYu with an urgent need: turn this challenging waste into strong, dependable plastic molded pallets.

Local suppliers had turned them down due to the material’s complexity.

After discovering ThoYu’s expertise in plastic recycling and molding through an online search, the client contacted us—hopeful yet uncertain.

Solving the “Unrecyclable”

Confronted with the difficult material, ThoYu quickly assembled a special task group. Analysis confirmed it: producing pallets directly from pure cable skins was not feasible—it wouldn’t meet performance standards.

We introduced a creative fix: blending the cable skin compound with inexpensive, readily available rice husks.

This blend not only cut material costs but also drastically improved the strength, durability, and sustainability of the resulting cable skins pallets. The client embraced the innovative proposal.

II. Engineering the Fully Automated Factory

Understanding Japan’s pressing issues—high labor costs, an aging workforce, and hiring challenges—the client required a production line with maximum automation. ThoYu delivered a smart, tailored unmanned system:

✅ Core Setup

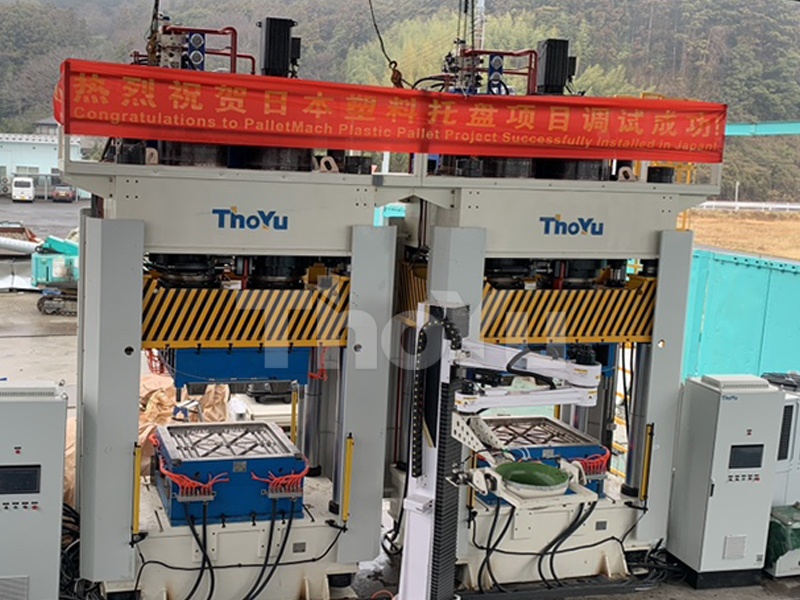

2 fully automatic Plastic Pallet Molding Machine, 2 chillers, and 2 custom mold sets dedicated to producing cable skin pallets.

(Plastic Pallet Molding Machine)

✅ Robotic Handling

2 advanced robotic arms with unique scoop-style grippers for pinpoint material handling and pallet retrieval.

(Customized Robotic Handling)

✅ Intelligent Flow

A high-precision weighing system, automated conveyor belts, and a palletizing stacker—all integrated for smooth operation.

(The back of the production line)

✅ Process Upgrade

Re-engineered feeding and plastification with weighted dosing for better accuracy than injection molding, guaranteeing consistency in every cable skin pallet.

III. Mastery Across Borders: From Challenges to Smooth Operation

ThoYu engineers flew to Japan to supervise installation and fine-tune the system.

They adjusted processes on the fly when actual materials differed from samples, reconfigured layouts, and tackled every unforeseen issue with expertise. The result? A production line that adapted quickly and operated flawlessly.

Outcomes: The High-Quality Cable Skins Pallets

After 14 months of dedicated effort, what was once waste is now a high-value product:

(Finished pallet showcase)

Superior Quality

Smooth finish, no sharp edges, dimensional uniformity; greatly improved strength with high resistance to moisture and chemicals.

Outstanding Performance

Capable of supporting up to 6 tons static load and 1.5 tons dynamic load. Custom designs can push the dynamic load up to 2 tons.

Smart Structural Design

Precision-molded with internal reinforcements for extra strength and stackability. Multiple anti-slip textures available, combining safety and visual appeal.

Eco-Friendly & Efficient

Material utilization reaches 99%—dramatically reducing waste. Offers significantly lower cost than conventional injection molding.

Whatever difficult plastic waste stream you are dealing with, ThoYu is here to partner with you— delivering innovative, customized solutions that benefit both your business and the planet.

Post time: Aug-21-2025