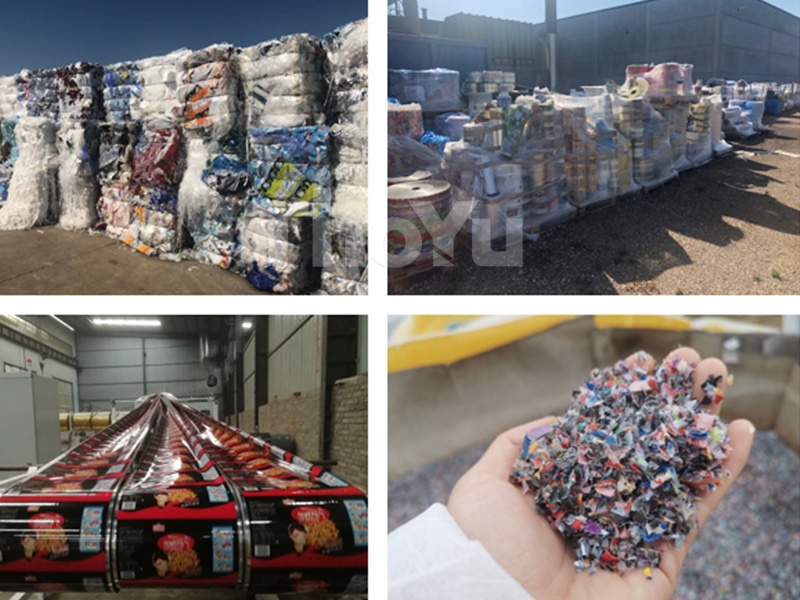

The global mountains of mixed waste plastics are eroding the land and polluting the air. From TV shells in Chile, Agricultural plastic films in Xinjiang, food bags in Iran, and composite waste plastics in Japan… these “non-recyclable” pollution sources are transformed into tens of thousands of tons of high-strength pallets on the ThoYu production line.

1. Waste plastics from multiple countries around the world are transformed into molded Plastic pallets.

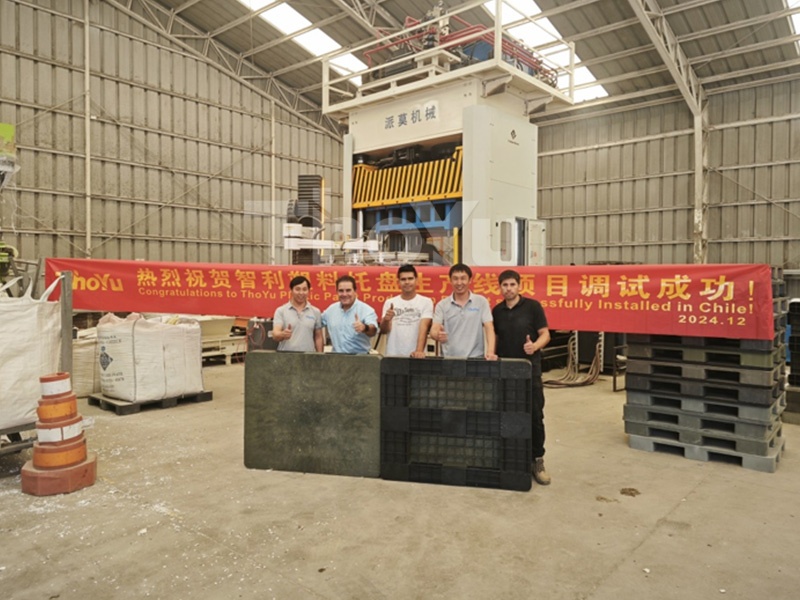

- Chile

Customer’s raw materials: polyethylene sheeting, TV breakage materials, and large bag materials (mainly polypropylene).

Engineer’s successful debugging and pallet samples.

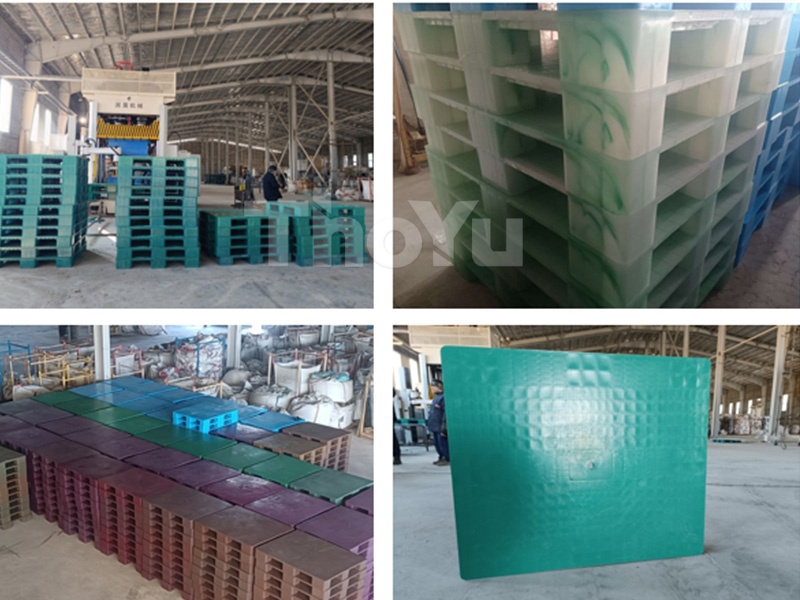

- Iran

Customer raw materials: Waste food packaging bags, plastic pallets, plastic baskets, beverage bottles (polypropylene, polyethylene, high-density polyethylene).

Actual photos of plastic pallet products.

- Spain

Customer raw materials: Packaging waste, plastic film waste (polypropylene, polyethylene, low-density polyethylene).

Actual photos of plastic pallet products.

- Japan

Customer raw materials: polyvinyl chloride, acrylonitrile-butadiene-styrene copolymer, polypropylene, wood powder.

Actual photos of plastic pallet products.

- Mexico

The raw materials of the customers: discarded plastic packaging, toothpaste tubes, etc.

The actual shot of the plastic pallet product.

- Canada

The customer’s raw materials: polyethylene particles and plastic pallets.

The successful debugging and a sample of the pallet.

2. Domestic waste plastic landfill turns into a gold mine.

- Government cooperation project in Xinjiang

Raw material source: abandoned agricultural plastic films that have long polluted cotton fields.

Project highlights:

Government cooperation on environmental protection projects, achieving “pollution source → high-value product” transformation;

Creating a win-win situation of economic benefits and ecological restoration;

Received a special report by CCTV News!

- Shandong paper mill waste plastic turned into a molded pallet project

Raw material source: waste plastic generated after the cleaning of the paper mill pulp.

Project highlights:

Raw material fully automated plasticization and quantitative molding process;

Unique design at the bottom of the pallet ensures stability during long-distance transportation.

Reduces losses during the logistics process.

3.The 5-step code for garbage rebirth

- Intelligent sorting: The Metal detector automatically “mines”, protecting the production line.

- Deep purification: Multi-stage rinsing + polishing cleaning, both purity and cleanliness meet standards;

- Anti-block supply: Continuous, dense supply, no bridge formation;

(Plastic Extruder Machine)

(Plastic Extruder Machine) - High-pressure cold pressing: The ThoYu press machine adopts a high-precision drive system combining hydraulic power and servo control technology, solving the shortcomings of the traditional hydraulic system as “coarse and forceful”, while saving 15%-20% energy.

- Mechanical hand palletizing: It takes only 20-30 seconds to transport and stack one pallet.

4. Why do global customers choose ThoYu?

- Low raw material requirements: Various sizes and forms of waste plastics and composite materials, no need for sorting, can be recycled and reused, reducing raw material costs by 50-75%.

- No need for granulation: The processing process does not require granulation; only simple crushing can meet the requirements, resulting in energy saving by 35%.

- High safety: The equipment is fully equipped with protective covers on the outside, in line with ISO 13857 mechanical safety standards.

- Wide application range:ThoYu has designed over 10 mature pallet styles for customers, not only elegant and generous, but also ingeniously solving the anti-slip problem of goods during transportation, ensuring the safety and stability of the goods.The dynamic load capacity of the pallet can reach 1-1.5 tons; the Static load capacity can reach 4-6 tons.In addition to pallets, it can also produce turnover boxes, manhole covers, and other plastic products.

- High automation level: PLC control system, optional mechanical arm, reducing manual labor by more than 70%.

- Low investment and high profit: Low raw material/energy cost, less manpower requirements, comprehensive profit margin exceeds 40%.

Converting waste plastics into high-performance,high-value green molded Plastic pallets can reduce costs, expand the market, and facilitate exports, bringing economic benefits and brand value to the enterprise.

ThoYu provides various waste plastic recycling solutions, which can be customized with different sizes, weights, and styles of molded Plastic pallets according to customer needs.

With the tightening of global plastic restrictions and the promotion of the circular economy, the market for waste plastic molded Plastic pallets will continue to expand. A trillion-dollar blue ocean, it’s the right time to enter now!

Post time: Aug-18-2025