In the vast palm plantations of Malaysia, a persistent challenge troubles global palm industry giants: over 300 tons of Palm Fiber Waste (fibrous waste left after oil extraction from palm fruits) accumulates daily. This Palm Fiber Waste material is either sold at low prices to mattress factories and boiler plants or left in open-air stockpiles – causing environmental pollution and incurring additional disposal costs.

Until April 2024, a breakthrough emerged when a client discovered ThoYu’s plant fiber molded pallet solution(Click here for more information). Like a lightning strike, it shattered the deadlock: Could these Palm Fiber Waste be transformed into sturdy, durable pallets? Solving waste disposal while generating new revenue–a true win-win!

01 From Waste to Treasure: One Can of “Game-Changer” Adhesive Makes the Difference

In September, ThoYu’s team visited the client’s palm plantation and factory. By October, processed palm fiber raw materials arrived at ThoYu’s facility for testing.

( palm fiber raw materials)

This trial used a novel MDI adhesive. The results stunned the client:

(MDI)

The pressed pallets exhibited a mirror-like sheen, as if polished with wax–instantly elevating product quality.

(pallet surface detail)

More remarkably, the surface resembled a uniform oil coating, boosting waterproofing and moisture resistance. Even in humid warehouses, they resisted deformation and mold, outlasting conventional pallets.

(pallet stacking)

02 Efficiency & Cost Revolution: A Masterstroke!

Speed breakthrough:

- Urea-formaldehyde (UF) adhesive: 8-minute press time

- MDI adhesive: 180-second press time

→ 62.5% efficiency gain → Higher daily output!

Operational simplicity:

- MDI: Ready-to-use; stable quality even for beginners.

- UF: Requires water dilution and ratio adjustment – prone to human error.

Cost efficiency:

MDI unit price > UF, but usage is only 4% of pallet weight (vs. UF’s 15%)

→ Lower overall cost + superior quality = Unbeatable value!

Impressed, the client immediately ordered 2 Plant Fiber Processing Machine(Click here for more information) + full production line, specifying MDI adhesive.

03 Export Hurdles? Local Market Holds Bigger Surprises!

Post-production, plans to export palm fiber pallets to China faced challenges: 6% tariffs + 13% VAT eroded price competitiveness.

However, the demand for environmentally friendly products in the Malaysian domestic market has risen, and local enterprises are now seeking cost-effective industrial pallets.

To meet diverse needs, the client inquired: “Can you produce pallets in different sizes/styles?”

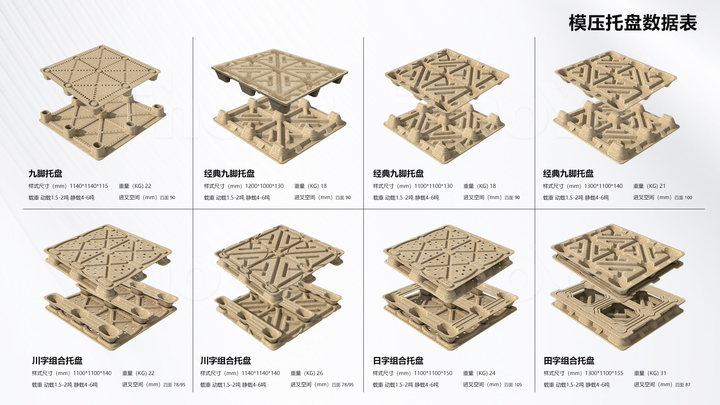

ThoYu offers 10+ proven pallet designs. Switching sizes/styles requires only a mold change on the press!

(Pallet design variations)

From mountains of waste to high-demand eco-pallets, this company’s turnaround leveraged not just resourceful recycling – but strategic technology adoption (MDI adhesive) and market agility (local focus).

Post time: Jul-31-2025