The abandoned agricultural plastic films buried deep in the soil are nearly impossible to degrade for Hundreds of years, eroding farmland, poisoning the ecosystem, and causing far more harm than ordinary plastic pollution! However, these troublesome pollution sources are excellent raw materials for manufacturing Molded Plastic Pallets!

“The scam” high-priced production lines frequently fail?

At the beginning of this year, a Korean company purchased a certain brand of pallet production line at a high price, hoping to process the mountains of abandoned agricultural plastic films. But they encountered a series of difficulties:

- Product defects: The pallets were deformed, warped, and uneven, unable to stably carry goods.

- The wall thickness was uneven, prone to cracking;

- The edges and holes were rough, prone to scratching goods or workers.

- After-sales evasion: The supplier shifted the blame, claiming “it’s a mold size issue,” forcing the customer to incur additional costs.

- Production line paralysis: The equipment was idle like scrap metal, occupying space without producing anything.

A test once turned the situation around!

The customer searched the website and came across ThoYu’s waste plastic recycling molding equipment. The online communication was smooth, and the customer decided to send in their raw agricultural plastic film materials.

After receiving the raw materials, we immediately arranged for the factory to conduct tests. The results were exciting!

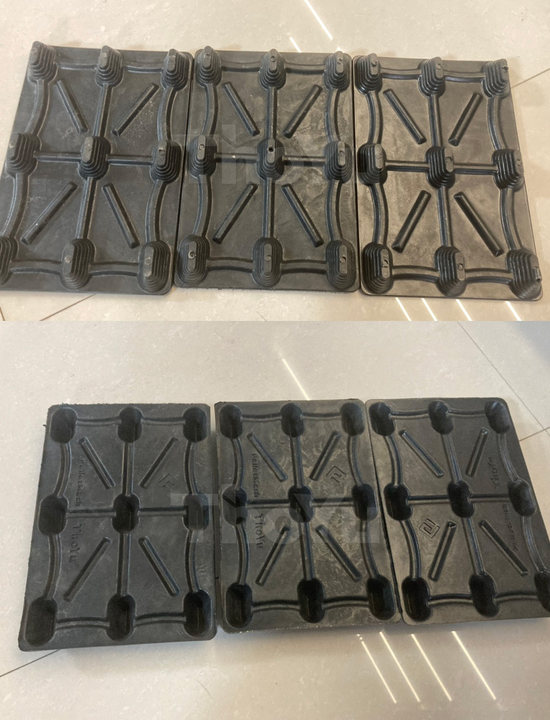

The small molded plastic pallets were uniform in thickness, smooth on the surface, flat at the edges, and precise in the holes.

Dynamic load tests, strength tests, and other test results all met the required standards.

Why were the results so different, even with the same waste material?

Hard core equipment + precise technology = absolute quality guarantee!

1. ThoYu’s plastic extruders, with their unique design, have significant advantages such as high output, low energy consumption, and stable extrusion, especially suitable for large-scale mold production.

Compared to other plastic processing equipment, the manufacturing costs and operating costs are lower.They can flexibly handle a variety of plastics and have a wide range of applications.

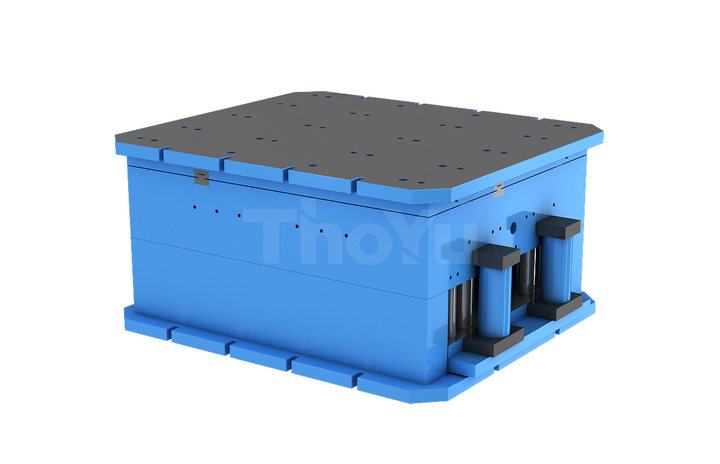

2.ThoYu’s Plastic Pallet Machines feature a unique three-beam, four-column structure, which ensures stability, and the four-column guide guarantees precise mold closure.The use of servo motors ensures that the working noise is extremely low, and the press runs smoothly, with precise control.With the Siemens control system and Schneider electrical components, the quality is guaranteed!

3.ThoYu’s molds are made from P20 and 45 steel, with P20 mold steel used for the surfaces that come in contact with the plastic.

P20 mold steel: Known as the “king material” for plastic molds, it offers uniform hardness, rust and corrosion resistance, and smooth surfaces after cutting and grinding—perfect for high-precision plastic products!

4. In addition to the leading equipment, ThoYu’s molding process offers several advantages:

* Low raw material requirements: Not only can abandoned agricultural plastic films be “turned into gold” using ThoYu’s Plastic Pallet Machines, but cable skins, plastic bottles, plastic waste, paper factory materials, and other waste plastics can also be reused.

* No need for Pelletizing: Only simple crushing is required to meet the necessary requirements.

* Rich product variety: In addition to various sizes and patterns of pallets, ThoYu’s Plastic Pallet Machines can also produce many other products, including plastic manhole covers, logistics turnover oxes, sorting trash bins, etc.

* Low investment, high profit: The investment is only half that of an injection molding machine, but the profit is doubled!

* High safety: All external equipment is equipped with covers to ensure safety during the production process.

From shipment to commissioning, we always aim to be ahead of the customer!

Given their previous failures, the customer lacked confidence in the success of the new production line configuration. We quickly sensed the customer’s anxiety and proactively proposed a thorough check of the details.

“Self-installation might cause production line paralysis due to accessory confusion or debugging errors. How does ThoYu ensure ‘out-of-the-box readiness’?”

Our business personnel will categorize and package the accessories, label them, and provide diagrams.Before shipping, the factory will perform no-load tests to ensure smooth operation.The ThoYu engineers will provide remote guidance to identify and resolve any issues promptly.

“The factory’s existing electrical load is limited, and ThoYu’s extruders have higher power. Does the entire factory’s electrical system need to be renovated (which is costly and time-consuming) to enable quick production?”

The ThoYu equipment is equipped with a PLC system, supporting 24-hour automated operation. It can operate at full load during the night and be used in a staggered manner with other production lines.

After a series of patient and thorough explanations, the customer immediately made a decision: pay the deposit and sign the plan!

“With such excellent products and services, I will also recommend them to my colleagues!” This proactive “endorsement” is more powerful than any advertisement!

Post time: Jul-25-2025