As the global wind power industry experiences rapid growth, a pressing challenge has emerged: how to handle the massive volume of retired wind turbine blades, which have a typical lifespan of 20–25 years. The breakthrough solution lies in the wind blade recycling machine, which transforms industrial waste into valuable resources.

The Challenge of Retired Wind Turbine Blades

Retired blades are primarily composed of fiberglass-reinforced plastic (FRP), a thermoset material known for its excellent chemical stability and physical strength. However, these same properties make the blades nearly non-biodegradable.

Traditional landfill disposal occupies large tracts of land for decades and risks contaminating soil and groundwater with residual chemicals. As a result, green, efficient, and large-scale recycling has become an urgent priority—and the wind blade recycling machine stands as the core equipment to address this need.

(raw material)

Powered by ThoYu’s Wind Blade Recycling Machine

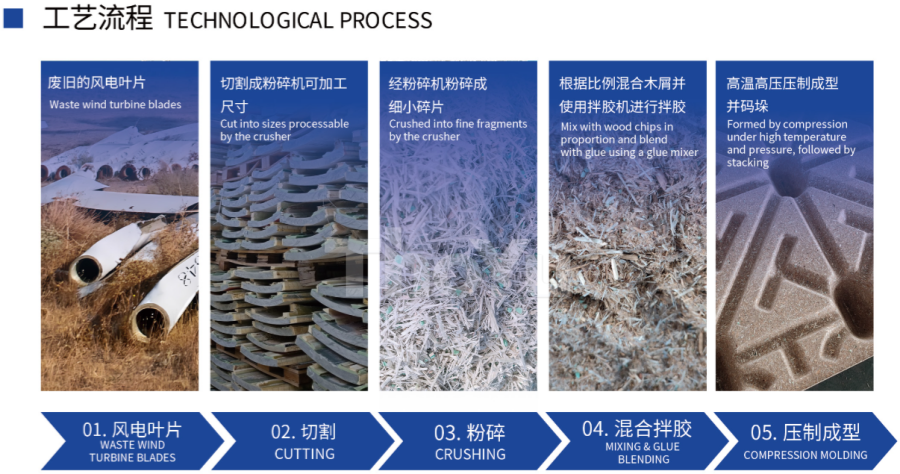

ThoYu leads a revolutionary recycling process centered around the wind blade recycling machine, converting retired blades into durable molded pallets through the following production process:

Crushed blade scraps alone have uneven density and lack sufficient strength for direct use. ThoYu’s wind blade recycling machine overcomes this by integrating the scraps with wood chips under high temperature and pressure, resulting in high-quality pallets.

(Processed raw material)

(Wind Blade Recycling Machine)

Advantages of Pallets Produced by the Wind Blade Recycling Machine

Pallets manufactured through this method excel in both performance and sustainability:

Extreme Durability: Stable across temperatures from -40℃ to 70℃, with no cracking or softening and minimal deformation during storage and transport. With less than a 2% expansion rate after 72 hours of soaking, they are suitable for high-humidity environments such as ocean shipping and cold storage.

Eco-Friendly & Certified: Made with environmentally friendly MDI glue, they comply with CARB NAF and EN 717-1 standards, reducing carbon emissions by 30% compared to traditional wooden pallets. Fumigation-free and ready for direct export, they save both time and logistics costs.

(Front of molded pallet)

(Back of molded pallet)

(Detail of molded pallet)

Lightweight & High Load capacity: Featuring a one-piece structure with reinforced ribs, they combine lightweight design with enhanced load capacity. The FRP component increases compressive strength and durability, easily passing dynamic load tests of up to 2 tons.

Versatile Applications of the Wind Blade Recycling Machine

The wind blade recycling machine is highly adaptable. In addition to the mainstream formula combining blade scraps with wood chips, it can also blend processed blade material with plastic to produce high-performance plastic pallets, meeting diverse needs.

Through this technology, tons of waste blades are transformed from waste into low-cost, green raw materials, providing enterprises with stable raw materials for pallet production.

If you have wind turbine blade waste, please work with ThoYu’s technical team. Let our advanced Wind Blade Recycling Machine help you convert waste into high-value molded pallets.

Post time: Dec-12-2025